Step by step photos that will help you disassemble an Authentic Eames Lounge. The lounge shown is a late 1970’s version with flat clips that hold the upholstery on. The earlier styles will differ in that they have a pair of round clips instead of all of the flat clips. The basic concepts are the same though.

Tag Archives: Shock Mounts

BEFORE / AFTER: One More Perfect Eames Lounge Panel

Bad break. Don’t fret, our panels will restore your chair back to perfection. We perfectly match color, grain, and finish. And we work with the highest quality rosewood veneers you can find. Notice that all of the details are perfect, right down to the plywood edge. Thanks for trusting us with your most precious pieces.

BEFORE…

AFTER…

BEFORE / AFTER: Trio of Red Aniline LCW’s

This trio of Red Aniline Eames LCW Lounge Chairs arrived in a sad state. Brown house paint, chips, rips, drilled holes in the backrests and chunks torn out of the spine.

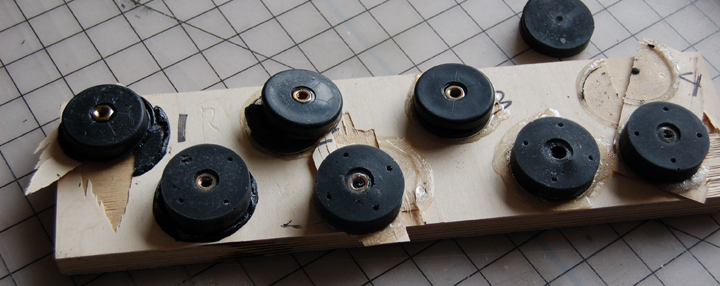

We did paint removal, extensive veneer work, perfect red aniline, chip repairs, and new shockmounts. Please notice the care we’ve taken to use as much of the original hardware as possible, use correct shockmounts, which accurately match the originals, and preserve the soul of each chair by ever so carefully keeping as much of the original aniline dye as possible.

This is now an impressive and valuable trio.

BEFORE…

AFTER…

BEFORE / AFTER: Eames Lounge Restoration, Original Ochre

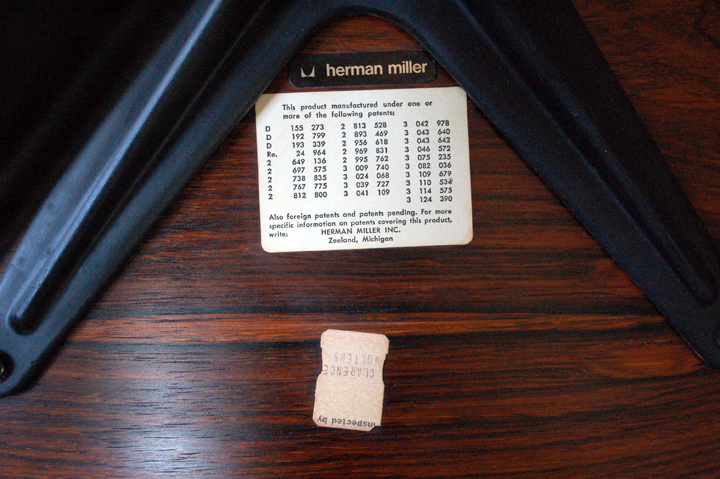

Our client asked us to restore this Eames Lounge and Ottoman to it’s former glory, and to preserve the rare original ochre leather. We were delighted to do the work. The wood panels have been repaired and restored, the leather has been cleaned and conditioned, and all of the original fragile paper tags have been preserved and are fully intact.

The integrity and value of the piece is preserved.

BEFORE…

AFTER…

BEFORE / AFTER: Eames Lounge Panel Repair, Another Perfect Match

BEFORE / AFTER: Mistreated Eames DCW’s Restored and Brought Back to Life

HOW-TO: Repair and replace Eames shockmounts for molded plywood.

These easy-to-follow instructions apply to replacing your aged shockmounts on all of the Eames molded plywood furnishings, including the DCM, LCM, DCW, LCW, CTM, and CTW.

What you’ll need:

Modern Conscience Wood Shockmount Adhesive

Modern Conscience Shockmount Adhesive Activator

Modern Conscience Shockmounts

Sandpaper (80-grit or 100-grit)

Denatured or Rubbing Alcohol

Modern Conscience Wood Finish Restoration Kit

You will find all of these parts on our website here.

1: Using sandpaper, remove all of the old epoxy.

Helpful Tip: Tape off areas around the mount where you want to protect the finish. It’s easy to accidentally drip or oversand. All of the original epoxy must be removed. A bond is only as strong as the weakest adhesive in there, so if you leave any of the old epoxy you’re providing an opportunity for failure of the bond.

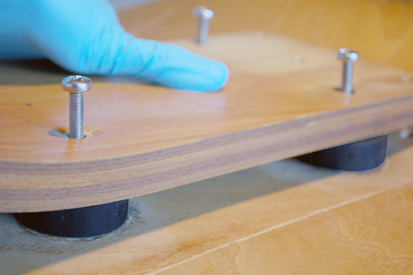

2: Use the chair frame to help you determine the exact location of the new shockmounts if the mounts you’re replacing don’t have obvious factory routed areas.

Helpful Tip: Use extra long screws in the frame. This will allow you to both move and carefully position the shockmount.

3: Clean the shockmount with denatured alcohol or rubbing alcohol using a lint-free cloth.

4: Clean the prepared wood surfaces with denatured alcohol or rubbing alcohol using a lint-free cloth.

5: Apply Modern Conscience Wood Shockmount Adhesive to the shockmount.

Helpful tip: Your puddle of glue should extend to within 1/4″ (6mm) of the edge of the shockmount. You want enough glue that it will slightly press out from underneath the shockmount on the sides, leaving no air bubbles. You do not, however, want so much that adhesive flows out from under it and runs everywhere.

6: Gently place the shockmount. Hold the shockmount in place and use a few strategic drips of Modern Conscience Adhesive Activator to secure the shockmount during cure time.

Helpful Tip: Do not press hard, you will force the glue out from under the shockmount and create what is called a “starved” joint. The weight of the shockmount plus some gentle pressure is enough to allow the glue to evenly lick up around the edge of the mount.

7: Allow 48 hours for the adhesive to reach full cure strength.

Helpful Tip: After the adhesive has cured check your work. Make sure that the adhesive has a nice bead around the edge. Anywhere the edge of the shockmount is exposed is an opportunity for forces to concentrate and will ultimately lead to failure of the bond. If you find an exposed edge, or just for good measure, you can apply a final bead of adhesive around the perimeter of the shockmount, again using the activator to help control placement of the adhesive.

8: Restore the exposed sanded parts of the fiberglass with a Modern Conscience Gel Coat Restoration Kit.

9: Enjoy your newly restored chair. You’ve worked hard, you earned it!

HOW-TO: Repair and replace Eames fiberglass shell chair shockmounts.

These easy-to-follow instructions apply to replacing your aged narrow mount shockmounts, as well as converting from the wide to the more versatile narrow mount configuration.

What you’ll need:

Modern Conscience Fiberglass Shockmount Adhesive

Modern Conscience Shockmount Adhesive Activator

Modern Conscience Shockmounts

Sandpaper (80-grit or 100-grit)

Denatured or Rubbing Alcohol

Modern Conscience Gel Coat Restoration Kit

You will find all of these parts on our website here.

1: Using sandpaper, remove all of the old epoxy.

Helpful Tip: All of the original epoxy must be removed. A bond is only as strong as the weakest adhesive in there, so if you leave any of the old epoxy you’re providing an opportunity for failure of the bond.

2: Use a base and the shockmount “bumps” on the shell to help you determine the exact location of the new shockmounts.

Helpful Tip: Don’t overly tighten the shockmount to the base, leave the screw a little loose so that you can flatten the mounts against the shell in their correct position.

3: Trace the shockmount locations with a marker.

4: Clean the prepared fiberglass with denatured alcohol or rubbing alcohol using a lint-free cloth.

5: Clean the new shockmount with denatured alcohol or rubbing alcohol using a lint-free cloth.

6: Apply Modern Conscience Fiberglass Shockmount Adhesive to the shockmount.

Helpful tip: Your puddle of glue should extend to within 1/4″ (6mm) of the edge of the shockmount. You want enough glue that it will slightly press out from underneath the shockmount on the sides, leaving no air bubbles. You do not, however, want so much that adhesive flows out from under it and runs everywhere.

7: Gently place the shockmount.

Helpful Tip: Do not press hard, you will force the glue out from under the shockmount and create what is called a “starved” joint. The weight of the shockmount plus some gentle pressure is enough to allow the glue to evenly lick up around the edge of the mount.

8: Hold the shockmount in place and use a few strategic drips of Modern Conscience Adhesive Activator to secure the shockmount during cure time.

9: Allow 48 hours for the adhesive to reach full cure strength.

Helpful Tip: After the adhesive has cured check your work. Make sure that the adhesive has a nice bead around the edge. Anywhere the edge of the shockmount is exposed is an opportunity for forces to concentrate and will ultimately lead to failure of the bond. If you find an exposed edge, or just for good measure, you can apply a final bead of adhesive around the perimeter of the shockmount, again using the activator to help control placement of the adhesive.

10: Restore the exposed sanded parts of the fiberglass with a Modern Conscience Gel Coat Restoration Kit.

11: Enjoy your newly restored chair. You’ve worked hard, you earned it!

WHAT TO KNOW: Eames shockmounts, epoxies, and adhesives.

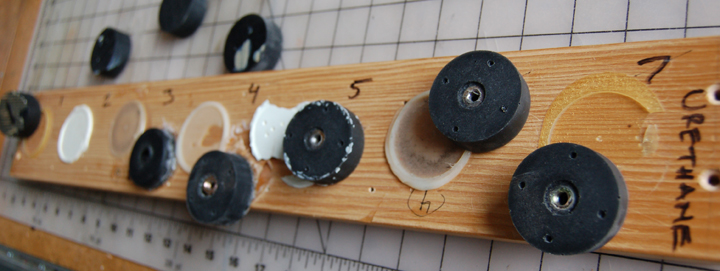

Product testing is a part of our routine. Epoxy, adhesive, rubber, and plastics technologies are literally advancing every day. To keep up with those advancements we routinely test a variety of consumer and commercial grade adhesives against what we’re currently using to make sure that we’re using the best.

For this test we tested the following consumer grade epoxies along with our current epoxy and some prospective new adhesives we have been considering. For obvious proprietary reasons we won’t divulge the source of the epoxies and adhesives we use in house (we do offer those on our website), but we will tell you a lot about what we learned about the products you can find at your local hardware store and how those compare to Modern Conscience products.

Epoxies and Adhesives Tested:

1: Loctite Plastic Epxoy (amber/clear)

2: Loctite Marine Epoxy (white)

3: Devcon Plastic Welder (cream)

4: Devcon 5-Minute Epoxy Gel (cream)

5: PC-11 Marine Epoxy (white)

6: Loctite Quick-Set Epoxy (cream)

7: Loctite Heavy Duty Epoxy (amber)

8: JB Weld (gray)

9: Loctite Super Glue Gel (clear)

10: Modern Conscience Current Epoxy

11: Modern Conscience Prospective Adhesive #1

12: Modern Conscience Prospective Adhesive #2

13: Modern Conscience Prospective Adhesive #3

14: Modern Conscience Prospective Adhesive #4

Testing Methods:

We are obviously interested in sourcing products which perform well on both fiberglass and wood so we tested all of the products in both scenarios. We have a seafoam fiberglass shell that came to us irreparable with a rip that has nearly divided it in two. This seat is always the victim in these experiments.

We are also interested in how the epoxies perform with a variety of rubbers so we compare tests with urethane, neoprene, and a proprietary tpe. Again, we’re looking for products that perform best across a broad spectrum

Each epoxy or adhesive was applied using the manufacturers directions. Cure time was extended beyond the manufacturer’s recommendations by an additional 24 hours for each product, for good measure. Then each mount was pried off using a torque bar to measure the torque required to remove each one. We performed this test three times on each fiberglass and wood for each product to account for any possible mistakes made in the gluing process.

How they Compared:

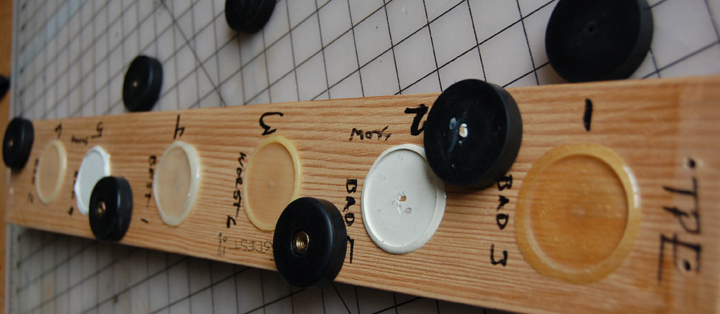

We grouped the results into four categories. We decided to call these categories horrible, bad, okay, and best because none of the consumer grade products performed as well as the current or prospective Modern Conscience products.

Horrible: Loctite Marine Epoxy, Devcon Plastic Welder, PC-11 Marine Epoxy, Loctite Quick-Set Epoxy

Bad: Devcon 5-Minute Epoxy Gel, Loctite Plastic Epoxy

Okay: Loctite Heavy Duty Epoxy, JB Weld, Loctite Super Glue Gel (good hold, but very, very brittle bond)

Best: Modern Conscience Current Epoxy, Modern Conscience Prospective Adhesives 1-4

What this Means:

Horrible epoxies and adhesives were those that had such little holding power you could almost pry them off with your fingers. The epoxy or adhesive easily separated from the fiberglass or wood, with little to no bond, meaning the rubber, wood, or fiberglass was unaffected.

Bad epoxies and adhesives were those that seemed to hold at first, but then came off fairly easy with the torque bar. No wood or fiberglass stayed stuck to these, although the wood, fiberglass or rubber may have been slightly impaired.

Okay epoxies and adhesives were those that would hold for a little while, but ultimately they would fail. These epoxies and adhesives would damage the fiberglass, wood, or rubber some, indicating that the bond had some strength.

Best epoxies and adhesives were those that were so strong the fiberglass failed, the wood failed, the rubber failed, or a combination of all three. With these epoxies the wood ripped apart, the fiberglass ripped apart, and/or the metal insert inside the shockmount bent. These were exceptionally strong epoxies and adhesives.

Current versus Prospective Modern Conscience Products:

We then proceeded with further tests to compare Modern Conscience’ Current Adhesive with the four possible Prospective Adhesives. They all performed fairly similarly so this time around we’re looking at a variety of factors. We again compare strengths on both fiberglass and wood. Then we also consider the look and feel, cost, and perhaps most importantly, ease of use.

The Results:

After carefully considering all of these factors we’ve decided to offer you a better range of products. Our new line is like nothing else you’ll find. It includes an an adhesive for fiberglass, an adhesive for wood, an activator that works with both, and an adhesive remover (no more panicking about mistakes, yay!). We know you’re going to love it, we already do.

Modern Conscience Fiberglass Shockmount Adhesive has been specifically tested to perform best in the application of a Modern Conscience shockmount to a fiberglass seat. This product is used for the installation of rubber shockmounts on fiberglass seats. It is rubber toughened, black, and reaches full cure strength in about 48 hours.

Modern Conscience Wood Shockmount Adhesive has been specifically tested to perform best in the application of a Modern Conscience shockmount to wood surfaces like the plywood panels of the Eames molded plywood series and Eames Lounge. It is a clear gel that reaches full cure strength in about 48 hours.

Modern Conscience Adhesive Activator can be used with both the Fiberglass and Wood Shockmount Adhesives. This product is used to accelerate adhesive to eliminate the need for clamping or taping and holds the shockmount in an exact position until full cure strength is reached. This product makes for an incredibly speedy and simple repair process. Please observe full cure times for the adhesives, even when using the accelerator.

Modern Conscience Adhesive Remover will dissolve cured Modern Conscience Adhesive within a few minutes. It can be used to correct repair mistakes as well as to separate fingers that have gotten stuck together with Modern Conscience Adhesive.

WHAT TO KNOW: The anatomy of a Modern Conscience Eames Lounge Shockmount.

We owe it to you to slave over all of the details and bring you the highest quality products available. Our Eames Lounge shockmounts are absolutely faithful to the originals, right down to the perforated metal panel embedded in the mount. This configuration gives the lounge it’s classic “bounce” and restores your lounge to its original condition. When you use Modern Conscience products in your restoration you know you’re using the best. And of course, Modern Conscience products are guaranteed.